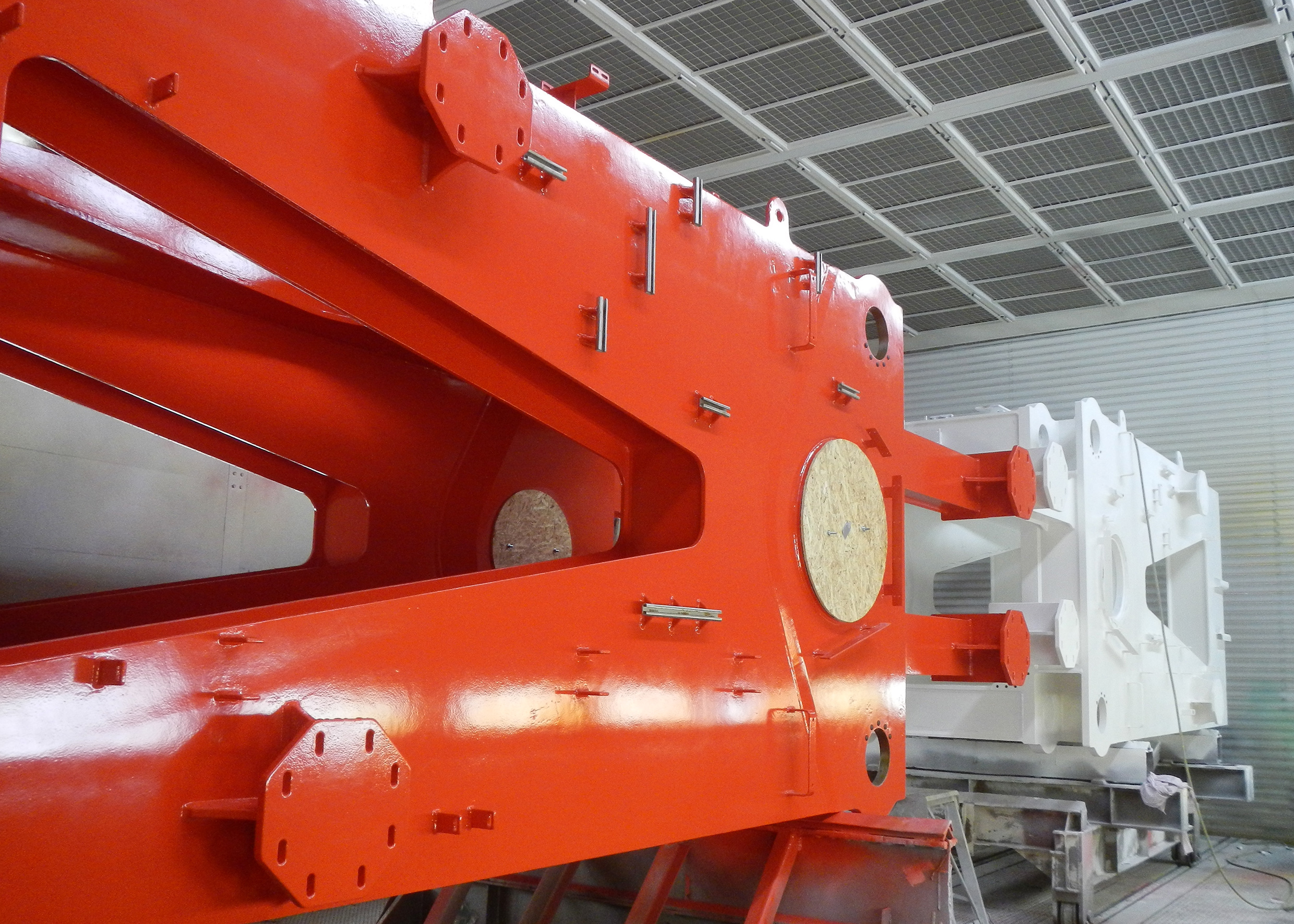

Corrosion Protection

The Steel Structure Production Plant is equipped with a modern corrosion protection center, featuring professional, technologically advanced painting and blasting booths.

The painting chamber (dimensions: 30 m x 8 m x 8 m):

- Spray application of protective coatings,

- Stable painting temperatures independent of weather conditions (maintained at 20–30°C),

- Significantly shortened drying times with drying possible up to 80°C,

- 95% efficient ventilation system ensuring a dust-free environment and overspray capture,

- Dual-zone operation capability,

- Lighting equivalent to natural daylight.

The blasting chamber (dimensions: 30 m x 8 m x 8 m):

- Abrasive cleaning with steel shot,

- Manual abrasive application by the operator,

- Abrasive circulation system with horizontal transport embedded in the movable floor,

- Surface cleanliness up to SA 2.5 – SA 3 and roughness up to 65 μm,

- Pneumatic abrasive cleaning system,

- Optimal working conditions with efficient lighting and ventilation.

We employ a team of highly qualified and experienced painting specialists. The high standards of our processes ensure top-quality results that meet international standards, including NORSOK.

Additionally, apart from providing corrosion protection for the steel structures we manufacture, we also offer professional anti-corrosion services for external clients.